Molds for Nanoimprint

About Molds for Nanoimprint

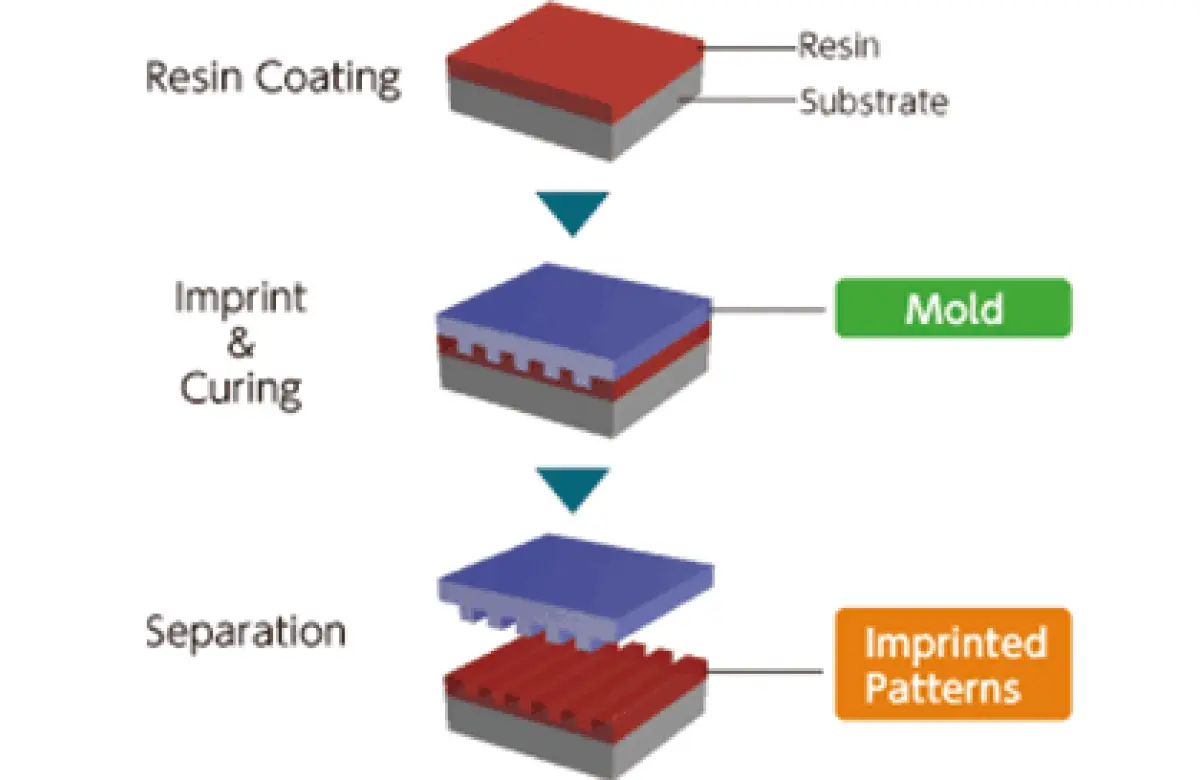

Nanoimprinting is a microfabrication technology that transfers patterns at the tens of nanometer level by pressing a mold, which serves as an original plate. Because of the simplicity of the process, nanoimprinting is expected to be a technology for mass production of microstructures at low cost and with good reproducibility.

feature-5

Nanoimprinting Methods and Mold Types

Methods of Nanoimprint

Lithography

Nanoimprint lithography can be roughly classified into two types: “UV method” and “Thermal Method”

■ UV Nanoimprint Method

The UV nanoimprint method replicates patterns by pressing the pattern on the mold against UV-curable resin, which is the hardened by UV Irradiation. Working at normal temperature is possible, giving this method the unique nature of allowing a high level of precision in the replication of patterns.

■ Thermal Nanoimprint Method

The thermal nanoimprint method replicates patterns by pressing the pattern on the mold strongly against thermoplastic resin, which is then cooled after being heated. Direct processing is possible for a variety of Products if they are made of materials that are softened by heating.

Mold Types

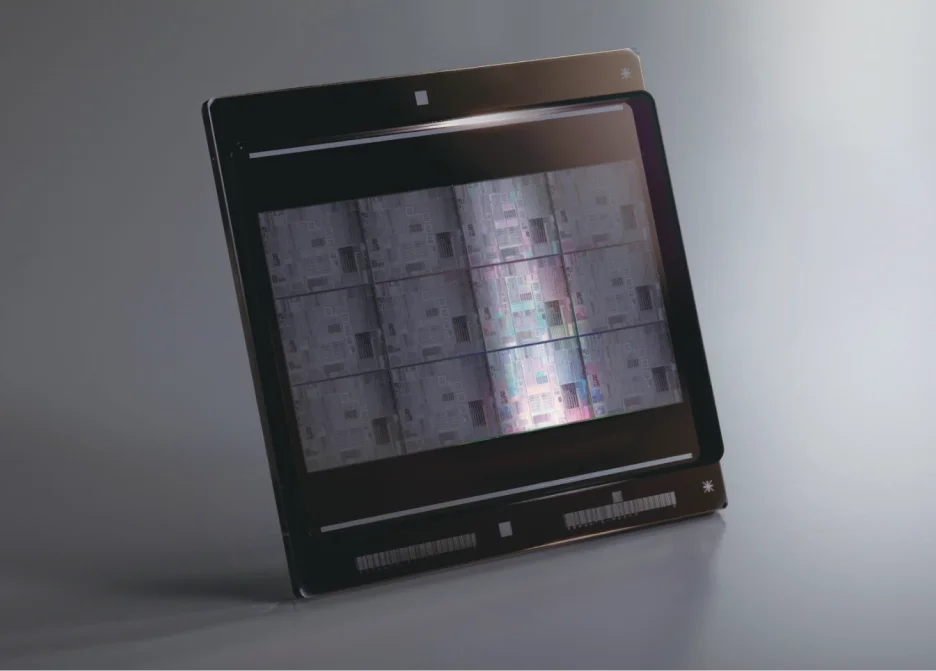

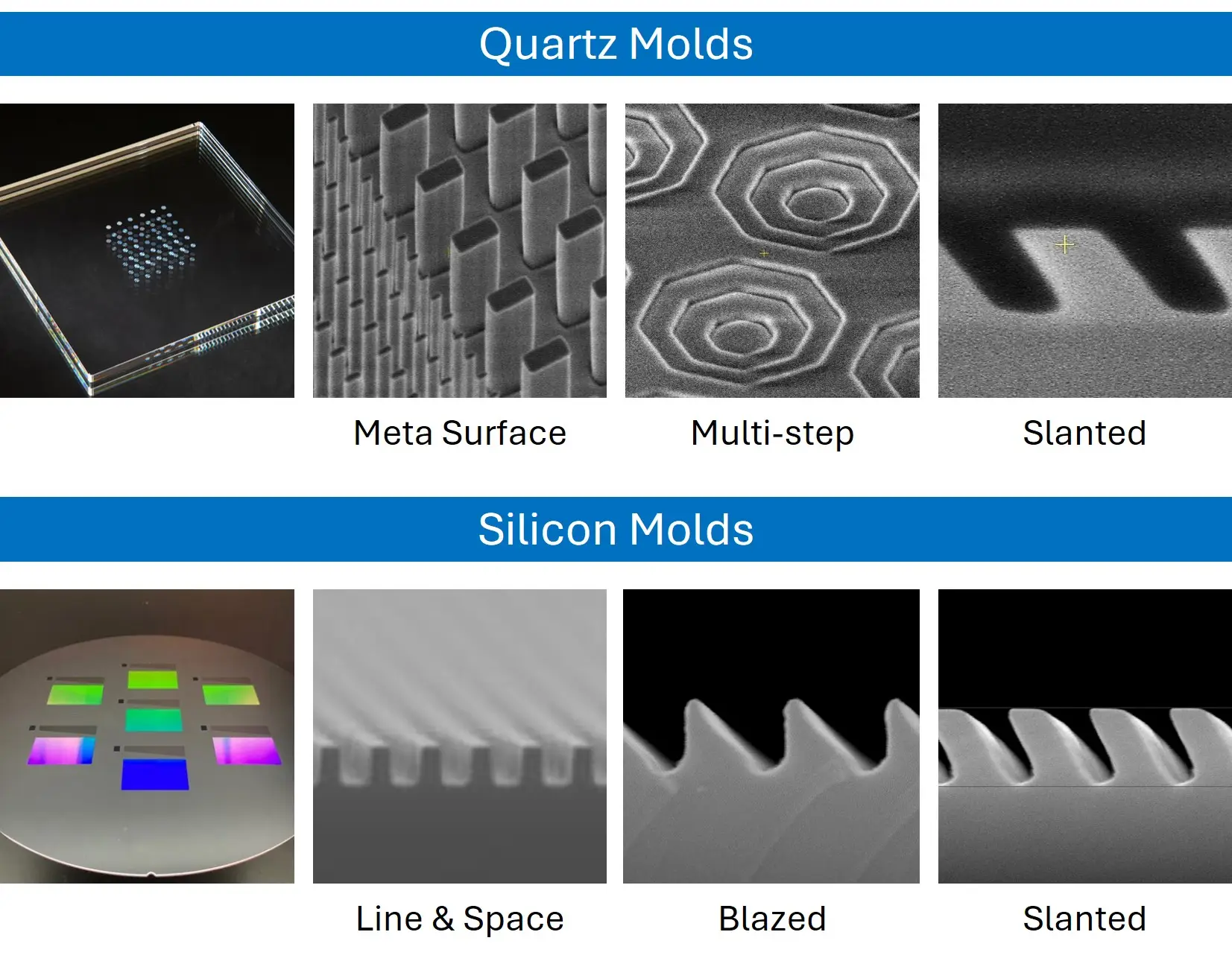

■ Quartz Molds

Tekscend Photomask's quartz molds are made of high-quality quartz substrate equivalent to that used for semiconductor photomasks, and have excellent stability and flatness. By applying the semiconductor photomask manufacturing process, our molds are capable of producing high-resolution patterns in the tens of nanometers. We also develop and manufacture molds with multi-step structures to meet a wide range of needs. Substrate size: 152 x 152 x 6.35 mm (t)

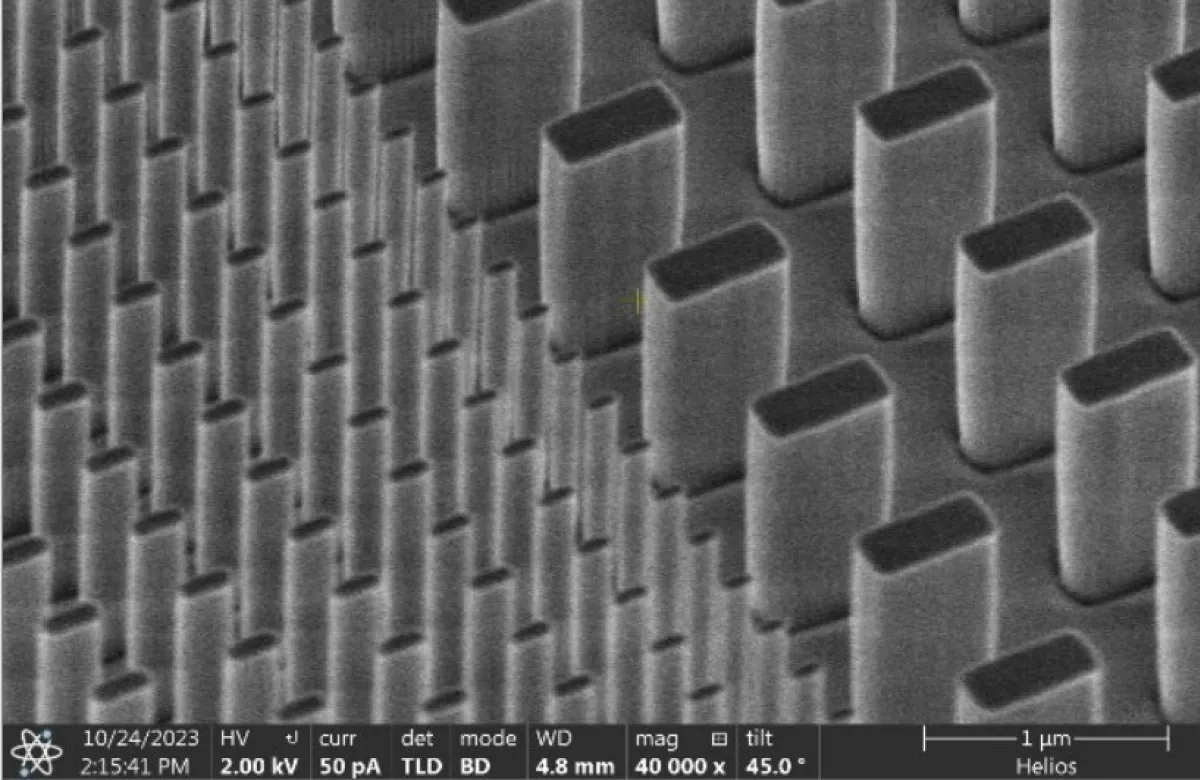

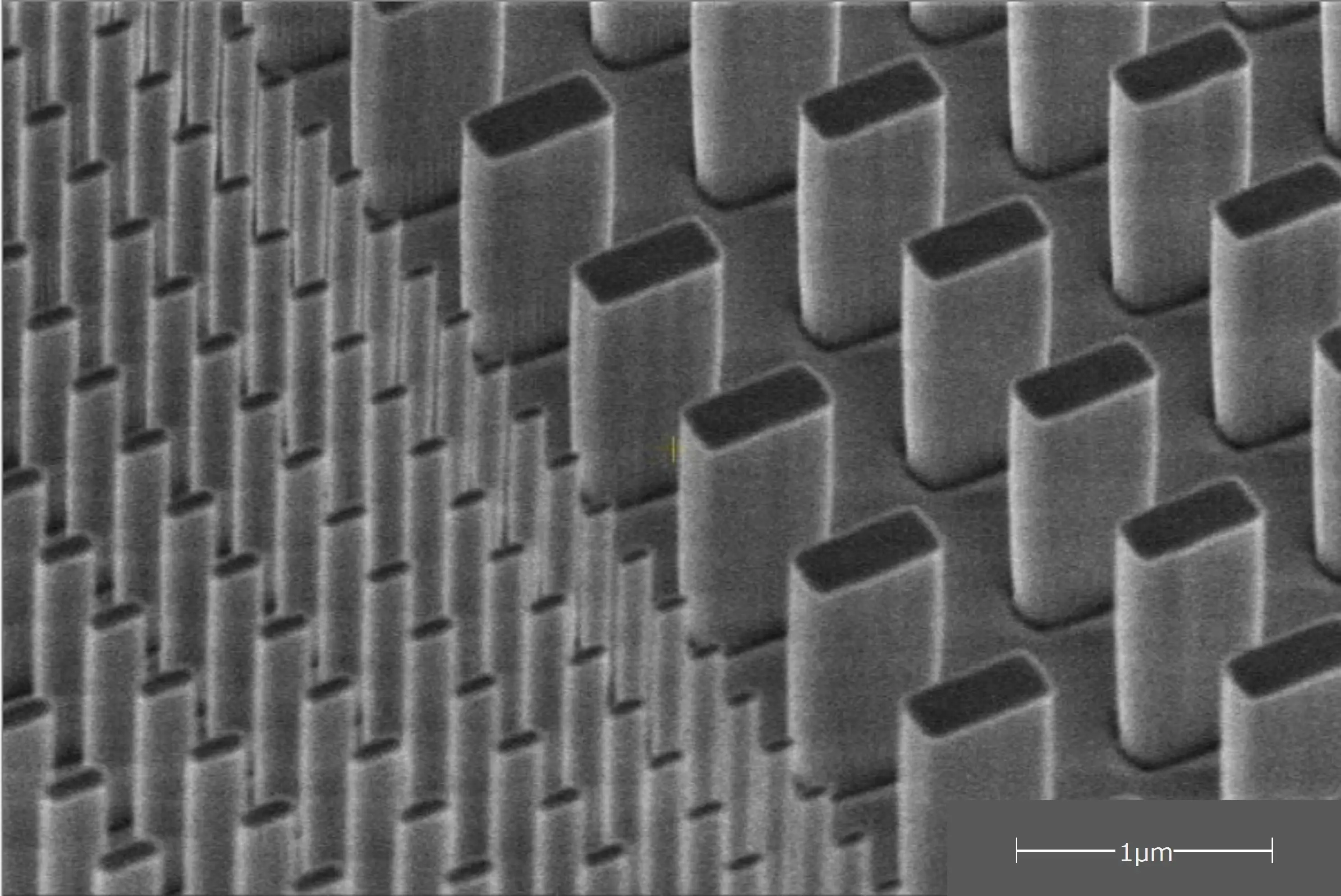

■Silicon Molds

Tekscend Photomask's silicon molds are manufactured by drawing a precise pattern on a photosensitive resist coated on a silicon substrate using an electron beam, and then deep drawing the pattern using a dry etching method. This process achieves the same high precision as quartz mold manufacturing and enables the production of silicon molds with high aspect ratio patterns and complex 3D shapes. Substrate size: 200 mm diameter (wafer thickness: 725 μm)

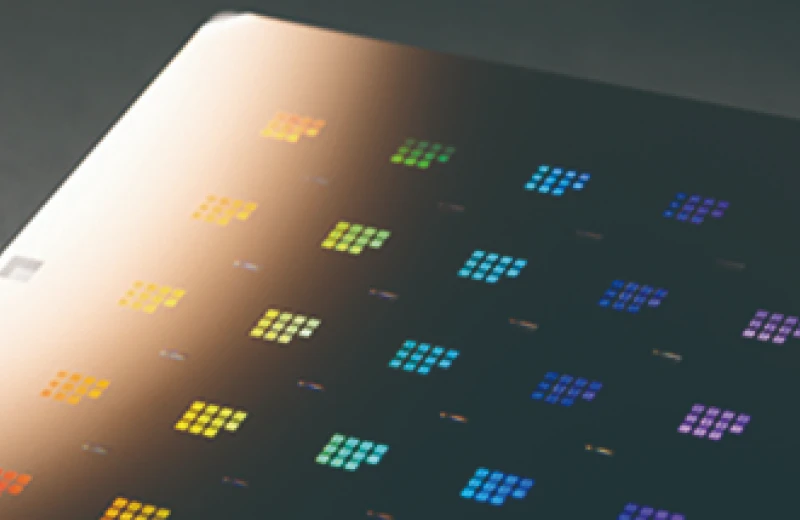

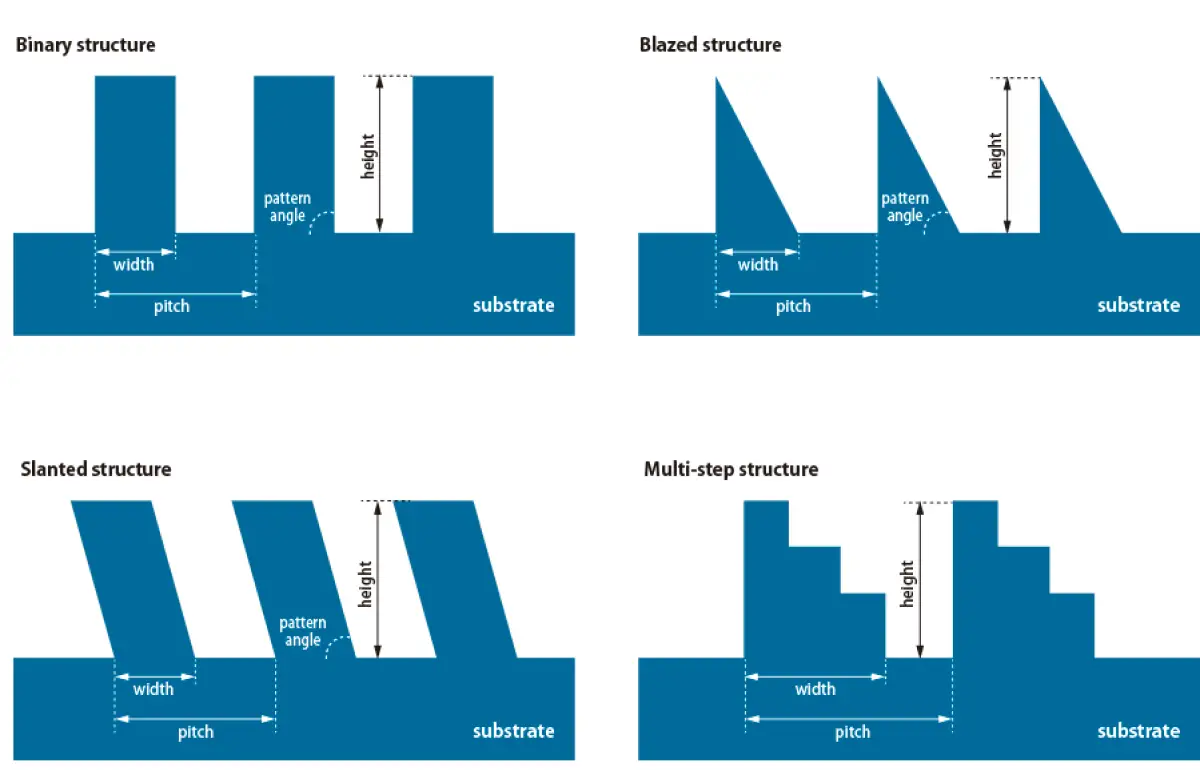

Pattern Shape Examples

We have already had extensive achievements as Toppan is offering various molds satisfying customers’ needs. We are also focusing on research and development, including the development of three-dimensional structure patterns.

Please feel free to consult us regarding your desired pattern shape, etc.

feature-5